Charcoal making or the production of charcoal out of wood, ikaskintza, is a job that dates back to ancient times. This undertaking acquired a relevant status in the last centuries with the emergence and development of foundries, and later on when the war broke out and charcoal started to be used as fuel for the house and the new means of transport. In the past century, in the 1950s, the consumption of wood charcoal dropped and other energy sources began to be used instead until it totally disappeared in the 1960s.

Charcoal making or the production of charcoal out of wood, ikaskintza, is a job that dates back to ancient times. This undertaking acquired a relevant status in the last centuries with the emergence and development of foundries, and later on when the war broke out and charcoal started to be used as fuel for the house and the new means of transport. In the past century, in the 1950s, the consumption of wood charcoal dropped and other energy sources began to be used instead until it totally disappeared in the 1960s.

Holm oak, common oak, beech and chestnut tree wood was employed to produce charcoal. The transformation of wood into charcoal is a delicate operation in which the wood is carefully heated but not burned; the charcoal burner must be extremely careful, or the lightest mistake could spoil the work of several days. Here follows a short account of the steps of the wood carbonizing process.

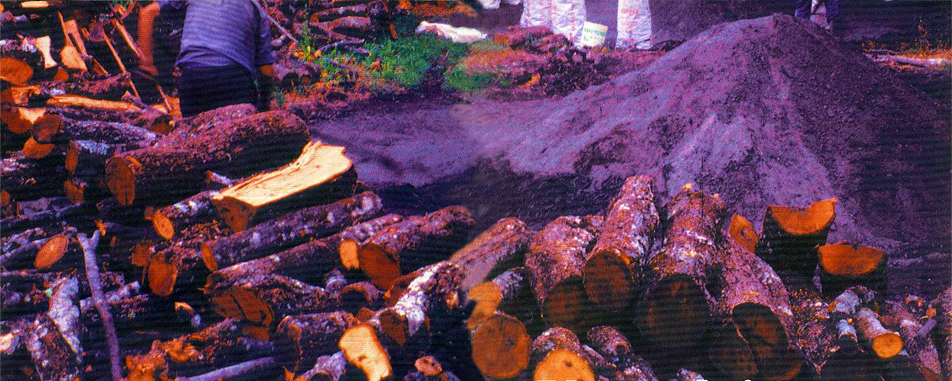

First, the wood is collected. To start with the tree is cut down, its branches removed and the trunk chopped to pieces; then the wood is transported to the site where the coal pit, txondorra or ikaztobia, is going to be built. The arduous task involves piling lots and lots of wood; four kilograms of wood yield approximately just a kilogram of charcoal, which gives us an idea of the toughness of the traditional charcoal making method. The pile of wood is stacked on flat ground, nearby a stream and sheltered from the wind.

Second, and after marking the location of the pit, a central shaft that serves as chimney is made to stand, and the firing is began at the bottom of the flue. The logs of wood are piled around the chimney: the heaviest at the bottom, medium-sized logs on top, and the lightest branches on a third level until a five-to-six-diameter pile is erected. Then the whole pile is covered with branches, leaves, fern or moss, and the remains of a previously charred pile, iduria, are added on top. Finally, the pile is lit and the charring commences.

Fire is set to the pile by introducing dry sticks and twigs through the chimney, then a shovelful of embers, and more sticks and twigs until the cavity is filled to the brim. Once the burn is complete, the chimney is plugged to prevent air from entering. The charcoal burner opens three or four holes in the upper part of the pile so that as air enters the wood sheds water and slowly burns. It is a procedure that requires a great deal of caution; if the holes are too big, the whole pile would burn in flames, and if they are excessively small the fire would extinguish. In the course of a few days, when the wood at the top charred, new holes are made further down, because the wood chars downwards.

The process takes ten to fifteen days to be accomplished and on-site attendance is required. The charcoal burner tends the wood pile day and night, with no long breaks or naps. This is not though his only commitment. As the wood carbonizes, the pile demeans or reduces in size, and the top part of the heap needs to be tapped with a wooden mallet so that the wood pile stays compact. Besides, twice a day it is refilled through the chimney to avoid open areas.

The process takes ten to fifteen days to be accomplished and on-site attendance is required. The charcoal burner tends the wood pile day and night, with no long breaks or naps. This is not though his only commitment. As the wood carbonizes, the pile demeans or reduces in size, and the top part of the heap needs to be tapped with a wooden mallet so that the wood pile stays compact. Besides, twice a day it is refilled through the chimney to avoid open areas.

When the smoke turns bluish, the wood is charred, and the pile is left to cool down for a couple of days. In the past the charcoal was loaded into sacks and brought down to the village in carts, on mules or even dragged on wooden pallets.

Loneliness, long spells of time in the mountain living in wooden huts, dirtiness, soot and endless care were the travel companions of the collier or charcoal burner. A real tough way of life!