In November, with the increase in the flow of rivers and streams, another trade acquired relevance: ironworks or water-powered forges. It was an occupation tough and important alike. Forges were the first iron manufacturing plants, equivalent to modern furnaces. There iron ore was smelted and refined into wrought iron. They emerged in the 14th century and their downturn started at the end of the 19th century. On the last Sunday of October, the owner of the forge invited all the villagers to a lavish meal, and at midnight the plant began to function. Work would not stop until the following Saturday at midnight. The forge kept operating from November till May.

In November, with the increase in the flow of rivers and streams, another trade acquired relevance: ironworks or water-powered forges. It was an occupation tough and important alike. Forges were the first iron manufacturing plants, equivalent to modern furnaces. There iron ore was smelted and refined into wrought iron. They emerged in the 14th century and their downturn started at the end of the 19th century. On the last Sunday of October, the owner of the forge invited all the villagers to a lavish meal, and at midnight the plant began to function. Work would not stop until the following Saturday at midnight. The forge kept operating from November till May.

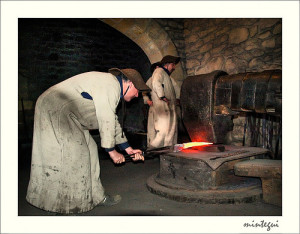

Forges were dark, hot and noisy places. The work carried out there was truly hard. The workers ended up completely black; they only wore a hat or other means of restraining hair and white linen clothing. The forge worked day and night, so sleep was scarce. Workers enjoyed the little sleep they could on site, on dirty maize husk filled mattresses placed on the floor.

There were four workers: two smelters, a hammer man who laminated the iron and an assistant. The assistant’s duty was to break down the iron ore with a hammer to the size of a walnut ready for the forge. The smelters were in charge of the hearth, of lighting it and loading it with charcoal and iron ore. They melted the iron ore to turn it into iron. The lump of iron was removed from the hearth, thrown to the floor and placed under the trip hammer. The hammer man opened the water flow control valve to make the hammer and its head work and kept moving the bloom under the hammer until it acquired the shape of an iron bar. The trip hammer would hit the iron over a hundred times a minute! Each operation lasted from five to six hours since the hearth was filled until the iron bar was produced.

Plenty of charcoal was needed in a finery forge. Let us bear in mind that it took approximately 500 kilograms of charcoal and as much of ore to fill the hearth each time; hence the importance of charcoal making. During the 19th century, with the flourishing of the forges, the charcoal making craft developed until the 1960s, when both trades finally disappeared.

Plenty of charcoal was needed in a finery forge. Let us bear in mind that it took approximately 500 kilograms of charcoal and as much of ore to fill the hearth each time; hence the importance of charcoal making. During the 19th century, with the flourishing of the forges, the charcoal making craft developed until the 1960s, when both trades finally disappeared.